Your employer has a ‘duty of care’ to ensure, as far as possible, your health, safety and welfare while you’re at work. In order to identify potential health and safety hazards in the workplace, it is imperative that a risk assessment is conducted and recorded for future reference.

A hazard is typically defined as a potential source of harm, or an adverse health effect on a person or persons. This simply means that anything that has the potential to cause damage or harm can be considered a hazard.

The most common hazards are usually physical objects, which include, but are not limited to unguarded machinery, pieces of furniture, or chemicals. However, these are the most often overlooked hazards, and this can be attributed to our familiarity with these objects. Whilst a flight of stairs can be seen as a hazard, we don’t necessarily view stairs as hazardous as we constantly use them every day.

Hazards are not always things that we can physically see. Exposure to intense and extreme temperatures, vibrations and noise levels can also be regarded as hazardous to our health.

Even if you are not responsible for conducting a risk assessment, it is important to be trained on how to recognise, assess and control hazards found in the workplace. To help you get started, we have addressed below some of the most common examples of workplace hazards, and how risks from these hazards can be prevented.

Slips, Trips and Falls

Slipping, tripping or falling is probably one of the most frequent causes of injury in the workplace, yet the most avoidable cause. In 2013, there were more than 1,200 slips, trips and falls reported to the HSA. Findings found that a quarter of those incidents led to the injured person missing over a month from work. The most common reasons why these accidents occur are: wet walkways, floor surfaces that are in disrepair, weather hazards (ice, rain, snow), improper or no signage, and inappropriate footwear.

How to prevent them?

Slips and trips can be easily avoided through good housekeeping (cleaning spills immediately, clearing debris, covering cables), having appropriate flooring (re-coating or replacing floors, installing mats, pressure-sensitive abrasive strips or abrasive-filled paint-on coating) and staff education.

Lack of First Aid

Unsurprisingly enough, although the purpose of first aid is to minimize injury and future disability, it is also a common workplace hazard. This can be due to insufficient training, inadequate facilities, and even companies having an appointed first-aider.

The Health and Safety (First-Aid) Regulations 1981 states that employers must provide adequate and appropriate first-aid equipment, facilities and first aid training so that the injured or ill can receive immediate help. What is ‘adequate and appropriate’ depends on the conditions of the workplace, so it is important that a thorough assessment of first-aid needs is undertaken.

How to prevent it?

It is essential to make sure that staff are trained in first-aid, and that their training is up-to-date. Another common mistake can stem from irregular replenishing of the first aid box after use. It is a good idea to make sure that it is checked frequently, and that items are replaced as soon as possible.

Ergonomic Hazards

Ergonomic hazards usually occur when your body position and/or your working conditions cause wear and tear on the body. These hazards mainly include the manual lifting of objects and poor lighting, which can effectively damage your eyesight. They are difficult to identify because the effects of the harm they cause to your health are not immediately recognized. Whilst short-term exposure to these hazards may result in soreness of muscles, the long-term effects can often result in detrimental long-term illness.

How to prevent it?

A number of protective measures can be employed to prevent this, such as using protective clothing and equipment when necessary such as padded gloves and knee pads, and by following safe work practices. When lifting heavy objects, you should never carry more than you can manage. It is also advised to not place weight on your back, but on your legs, whilst keeping the load close to your body. When possible, report early symptoms such as discomfort or numbness to your employer.

Equipment Hazards

Faulty electrical equipment is the cause of many injuries each year. Other equipment hazards may include lack of planned maintenance, lack of regular testing, lack of training of equipment, and faulty utility services, such as water, gas, electricity and compressed air. Health and safety law states that electrical and utility equipment must be well-maintained in order to prevent danger.

How to prevent it?

The type and frequency of these checks and the maintenance needed to depend on the equipment, where it is used, and the results of previous checks. It is important that checks are carried out by an expert, or someone who is suitably trained to do so. It is also essential to check with your supervisor how often these checks are required.

Lone Working

Lone workers are those who work by themselves without close or direct supervision. There are many hazards that a lone worker could encounter, such as accidents or emergencies arising out of their work, inadequate provision of first aid, inadequate provision of rest, hygiene and welfare facilities, and physical violence from members of the public or intruders. In December 2014, it was reported that a security guard had died from suspected carbon monoxide poisoning after it is believed he lit a fire in a portable cabin to keep warm.

How to prevent it?

Whilst it is perfectly legal to work alone, employers must access whether an employee is at significantly higher risk when working alone. It is essential that control measures are implemented in order to eliminate or minimise the identified risks, such as controlled periodic checks, automatic warning devices, and appropriate equipment for communication.

As a lone worker, you are responsible for looking after your own health and safety by co-operating with the employer’s safety and health procedures. You are also a duty to report to your employer if you feel that the provision of facilities is inadequate. You must also report any instances of accidents, injuries, near-misses and other dangerous occurrences.

Whilst some hazards pose an immediate danger, some hazards may take longer to manifest. Regardless, it is important that all types of hazards are addressed promptly. If you recognise a hazard which may have been overlooked by your employer, it is imperative that you report it immediately. Once a hazard has been identified, it is the duty of your employer to assess and eliminate the risks posed by the hazard.

Latest content – An interview with Julius Francis

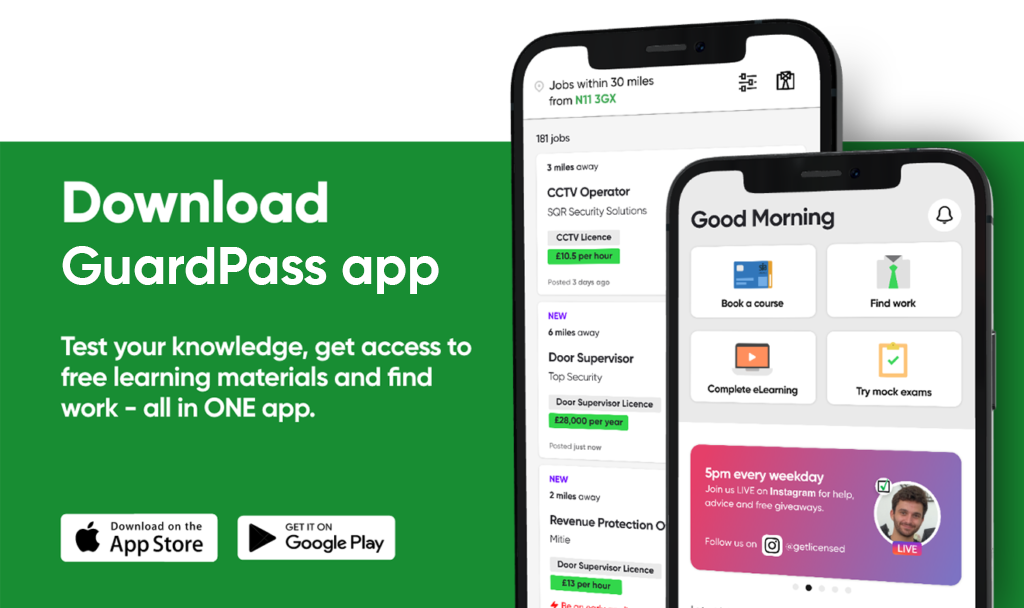

Get Training with the GuardPass app

The GuardPass app is the ultimate security app for those interested to get security training or work in the security industry. In the app, find the right security training course and book it easily. That’s not all, find all the resources to help you prepare for your course using our free mock tests, training videos and material, all in the app.

Once you’ve finished training and received your SIA licence, start applying for jobs, also available in the app!

Looking for jobs?

To find the latest security jobs, check out our Jobs Board, which has 1,000+ jobs from the UK’s best security companies.

If you’re on the hunt for a security job on the go, download the GuardPass app for all the latest jobs and more. The GuardPass App is available for download on the Apple App Store or on the Google Play Store.

Leave a Reply